Are you holding Master’s degree and looking for PhD positions – Fully Funded PhD Programs in Europe? University of Birmingham, England inviting application for funded PhD Programs or fully funded PhD Scholarship. University of Birmingham is one of the largest university in the world with thousands of employees, students, and research scientists are involved in the innovation of science and technology daily.

University of Birmingham has huge a campus in England and widely known as for its contribution in top notch education and research. The contribution of University of Birmingham is not only limited to natural sciences and engineering but it also offers high quality research as well as higher education in bio-medical sciences, social sciences, humanities, psychology, education, architecture etc.

1. EPSRC supported EngD: Formulation of Anolyte-Based Hand Sanitisers for the Control of COVID and Resistant Microbes.

Summary of Doctoral Project:

Within recent years there has been a need for improved, anti-microbial, technologies which can be used to combat microbial resistance. Over the COVID-19 pandemic, it has become increasingly clear that such technologies need to also extend to the prevention of viruses. Like many scientific advances it is possible to look to nature to find an answer. Hypochlorous acid is a naturally produced, essential chemical, within the body: created by the white blood cells during phagocytosis, to eliminate pathogens as part of the immune system. This can be replicated on an industrial scale through an electrolysis process, which splits aqueous salt solutions into their ionic species (anolytes and catholytes). As a result, it is possible to separate the anolyte (hypochlorous acid), however, such chemical species are meta-stable. Unfortunately, unlike in the body where they are used immediately, this poses a challenge to their long-term use.

Last Application Date: August 5th 2022

2. EPSRC supported EngD: Developing methods for Big Data capture in support of the Digital Twin for Investment Casting Shelling Operations

Summary of Doctoral Project:

The manufacture of single crystal turbine components via investment casting is critical to the efficiency of the modern jet turbine. Despite a very advanced and tightly controlled manufacturing process, there are still many unidentified and interacting variables that can affect component yields. One key factor is the shelling operation which creates the ceramic mould for casting. Control of the material formulation and processing variables are essential in making a mould with the correct properties and dimensions required for a defect free casting. Recent advances in 3D dimensional characterisation and in-process viscosity measurement provide an opportunity to generate “big data” pools that can be used to better respond to changes in the process. This data can also be fed into advanced process models or “digital twins” that allow the effects of changes to be understood downstream. As an EngD working within the HTRC you will develop data collection processes and make use of big data that becomes available to develop and validate the effects of shell build within the digital twin. This will require a fundamental understanding of the shell formulation effects on dimensional build and material properties and subsequent impact on a casting defect known as High Angle Boundaries.

Last Application Date: October 7th 2022

Looking For More Fully Funded PhD Programs? Click Here

3. ESPRC funded EngD: 3D printing of complex dressings for the regeneration of diabetic foot ulcers

Summary of Doctoral Project:

Diabetic Foot Ulcers (DFU) are open chronic wounds on the feet of diabetes patients that can lead to amputation if not managed correctly. DFU are a major burden to each patient and to the healthcare system as Ulcer healing times can range from one month to years and demand intensive wound care efforts. DFUs are subclassified into three categories: ischemic, neuropathic, and neuroischemic (most prevalent). In the case of neuropathic etiology, Ulcers are caused by lack of sensation in the foot leading to pressure points and abrasions which develop into open wounds. To address the high medical need in these patients, the treatment goal is a) to accelerate wound healing, b) to prevent recurrence, to c) avoid amputation ultimately. The team at UoB have developed a method to produce trilayered cell containing skin with a close resemblance to human tissues. In this project we will work closely to further develop this technology so that it is able to restore complex wounds, have the colour of non-pathological tissue, and ultimately seamlessly regenerate these often life changing wounds.

Last Application Date: August 5th

4. EPSRC funded EngD: Modelling of Resonant Acoustic Mixing Parameters

Summary of Doctoral Project:

Traditionally, multi-material blended components are mixed in planetary mixers, cast to blocks/blanks, and undergo subtractive machining to form shaped components. Composites such as syntactics and highly filled resin based systems are blended in rotary drums and other conventional blade based mixers over long periods of time, decanted, moulded to blocks and again undergo subtractive machining. These are both time consuming, wasteful and potentially hazardous when working with energetically-sensitive materials. Resonant Acoustic Mixing (RAM) is a novel powder/powder, powder/fluid and fluid/fluid mixing technology that has the potential to directly mix materials into the final net (or near net) component shape without further processing, removing or significantly reducing material waste, time and hazards. RAM is being trialled with a defence contractor and is showing excellent results to-date. However, modelling of this mixing technique is in its infancy and has not been addressed and thus, cannot be said to be optimised. Numerous mixing (intensity, time, pressure temperature), material (particle size, shape, pre-blending, order of addition) and tooling (shape, composition, mixing head space) parameters impact the efficiency of RAM and thus if modelled would add significant value in optimising the mixing process.

Last Application Date: August 5th

5. EPSRC supported EngD: Towards net-zero manufacture of chilled/refrigerated foods – the case of ready meals

Summary of Doctoral Project:

The Food Industry is the largest manufacture sector in the UK’s and the fourth highest industrial energy user. To contribute to the achievement of UK’s zero-carbon emissions targets by 2050, it is critical to act on those hotspots for energy demand and/or GHG emissions. One of these potential areas of action is the food cold chain – the manufacture and distribution of frozen, refrigerated and chilled foods is energy intensive and often involves the use of high-GWP (Global Warming Potential) refrigerants. In this context, this project aims to identify those food manufacturing scenarios that would lead to successful strategies for the transition to net-zero food supply chains focusing on chilled foods (e.g., ready meal foods), and working in partnership with Samworth Brothers. The project will combine techno-economic, environmental and/or policy aspects in an integrated approach for the design and evaluation of decarbonisation solutions, focusing on the comparison of different manufacturing paradigms – i.e., centralized vs. distributed manufacture – for specific ready meals, as exemplar of chilled/refrigerated foods. This approach is based on the development and implementation of suitable simulation/optimisation and decision-making tools, for which a high level of engineering and computational competence, coupled with adequate knowledge of (bio)process systems is desirable.

Last Application Date: September 30th

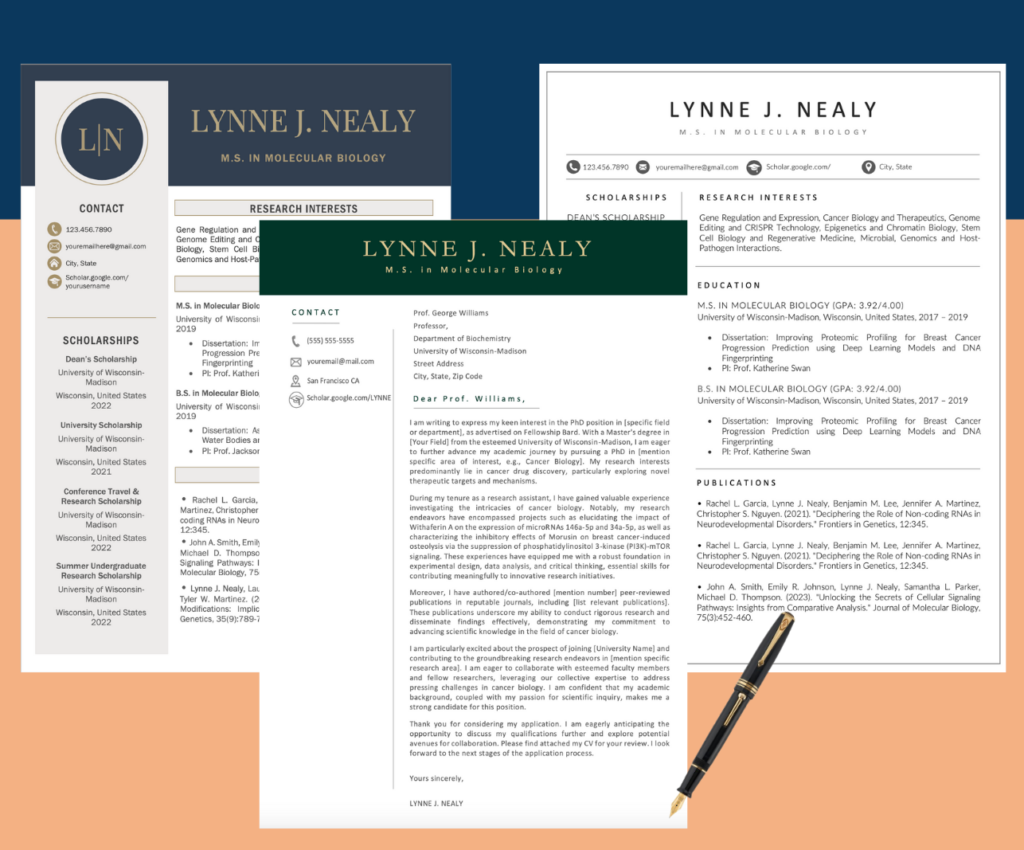

How to Write Cover Letter for PhD Program?

6. EPSRC supported EngD and industry funded EngD: Continuous processing of fibrous plant-based meat structure

Summary of Doctoral Project:

To provide consumers with ethical plant-based meat products, it is intrinsic that manufacturing processes are sustainable. Widely used screw extrusion type processes are energy intensive, and are limited in terms of fibrous structure generation, lipid inclusions and sustainable plant protein ingredients. Therefore, there is a need to design alternative, energy efficient processes which provide the necessary flow and structuring operations to produce such products at industrial scale and from a wider range of plant biopolymers. Improving our ability to create hierarchical aligned fibre structures will allow manufacture of products with superior sensory properties (e.g. juiciness, tenderness, flavour). The EngD project will advance the understanding of fibrous structure creation for the production of meat analogues in a continuous manner. The aim is to develop a novel, scalable technology for the manufacture of fibrous plant based materials in the presence of al lipid phase at different inclusion levels. The EngD candidate is expected to utilise a set of research tools including computational fluid dynamics (CFD), microstructure engineering and process rheology.

Last Application Date: September 30th

7. EPSRC supported EngD: Next Generation of Biodegradable Core-Shell Capsules

Summary of Doctoral Project:

EU microplastics regulations on synthetic polymer particles requires phasing out non-biodegradable capsule materials. Most polymers used for core-shell capsule formulations of pesticides are based on interfacial polymerization using diisocyanate and polyamines and are not biodegradable. FMC has developed unique biodegradable chemistry and this project aims to develop batch and continuous process options for multiple formulations, each with their own unique considerations: testing and selecting appropriate equipment, developing parameter windows for optimized yield and kinetics, and providing feedback to the chemist on ingredient selection. This project could take the direction of process optimization or process simulation via CFD and control. This work will be used to build an IP estate for chemistry and process. The experimental work would be carried out at the Stine Research Center in Newark, Delaware.

Last Application Date: October 7th

8. EPSRC supported EngD: Next Generation of Biodegradable Core-Shell Capsules

Summary of Doctoral Project:

EU microplastics regulations on synthetic polymer particles requires phasing out non-biodegradable capsule materials. Most polymers used for core-shell capsule formulations of pesticides are based on interfacial polymerization using diisocyanate and polyamines and are not biodegradable. FMC has developed unique biodegradable chemistry and this project aims to develop batch and continuous process options for multiple formulations, each with their own unique considerations: testing and selecting appropriate equipment, developing parameter windows for optimized yield and kinetics, and providing feedback to the chemist on ingredient selection. This project could take the direction of process optimization or process simulation via CFD and control. This work will be used to build an IP estate for chemistry and process. The experimental work would be carried out at the Stine Research Center in Newark, Delaware.

Last Application Date: October 7th

9. EPSRC supported EngD: Mechanistic understanding and design of sustainable solid fabric enhancer

Summary of Doctoral Project:

The project will investigate the formulation and action of dryer sheet coatings that is a major P&G business with sales in the region of $12 Billion Pa. Dryer sheets both assist the drying process and impart attractive texture and aromas to fabrics by transferring a formulated solid material from sheet to clothes within a tumble dryer. The governing relationship between formulation design and transfer efficiency is not however well understood; better understanding would lead to less waste and more efficient drying, saving both material and energy. Previous work between Birmingham and P&G studied drying both by measuring flows in working dryers [Drying Technology, 2021 doi.org/10.1080/07373937.2021.1918706] and by studying the transfer process at meso- and nano- scales, using AFM and micromanipulation probes, but was constrained to the current formulation to establish the basis of product action.

Last Application Date: October 7th